Jeff Rutherford, Boatbuilder and Surveyor from Richmond, California, visited TALLY HO in 2013, at our request, and made the following report. We are grateful to Jeff who did this work pro bono (we repaid his very reasonable expenses). The report is included here exactly as written by Jeff - I have made just two corrections of spelling.

I visited Tally Ho on Saturday Sept 14 in Brookings Oregon. She needs a lot of work but as with all projects the extent of work undertaken is largely dependent upon the owner and the depth of their pockets. It is my intention here to give estimates of hours to repair to a seaworthy state by professional shipwrights but not to turn her into a “gold platter”.

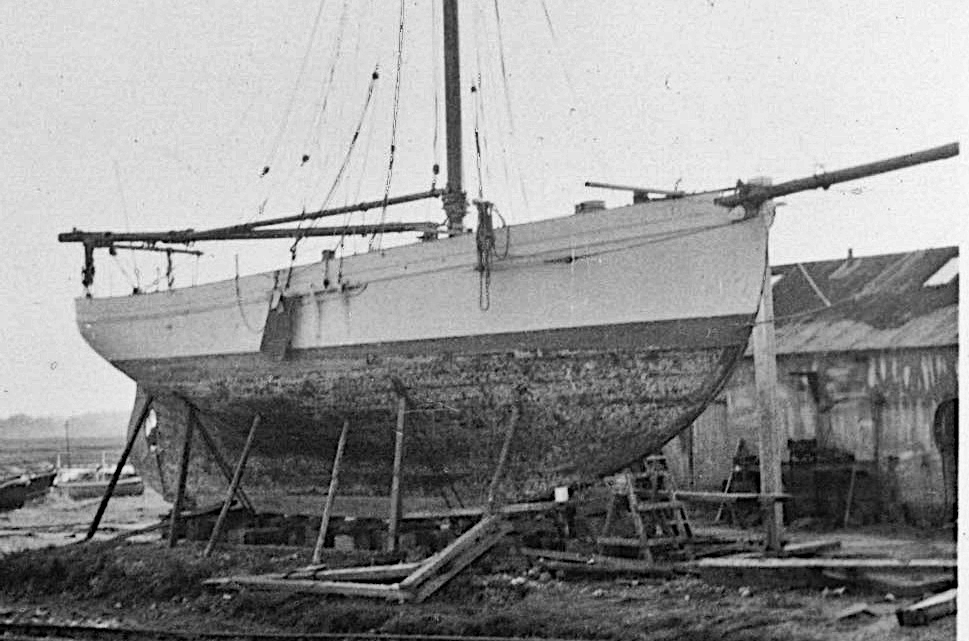

Tally Ho is planked with teak fastened with 3/8” copper rivets. I found the planking to be in excellent condition through out with the exception of 1 or 2 short planks, which could be replaced, or not at the owners wish. The port side had been stove in many years ago and a very professional job was done to repair the area.

The backbone and transom are in good condition. The upper 5’ of stem has been recently replaced and the workmanship seems adequate.

There is a hollow steel rudder lying on the ground the half I looked at could be salvaged. The hardware exists on both the boat and rudder. I imagine that the side down on the ground is in a similar state. In any case welding any necessary patches should be an easy task.

The deck planking is in poor condition as it was fastened with iron and edge fastened with iron as well. The heavy teak covering boards could be carefully removed and reused. There are 3 heavy teak king planks also in good condition and could be reused. I would plan to replace all the pine planking and the oak deck beams. I would put a plywood sub-deck, especially forward where the bowsprit pulls on the stem that is now 2 pieces.

The sawn bulwark stations were replaced recently. A very good job was done and they were not fastened in so reusing them is easy.

All hatches, skylights and coamings need to be replaced.

The framing is of heavy double sawn oak each futtock is sided 2” and moulded 3”. I believe you could get away with replacing 25% of it but could easily end up replacing 50%. The quality of the framing stock used was of a lesser grade than what is customarily used today.

There is no interior of any kind. Engine beds should be replaced, bulkheads installed, cabin sole and a new interior. Engine and systems.

There is no deck hardware except for the huge anchor windless. There are no spars or related hardware. No sails. No inside ballast.

WORK ESTIMATE

- The boat needs to be moved to the worksite. A very nice cradle exists to facilitate this. Or a shed gets build where she is now. I have no estimate for this.

- Build staging around the boat. Label and remove bulwark stations. Remove decking, cover boards and king planks. Shore across the sheer clamp remove and replace the deck beams. 240 hours plus $2,000 staging. $5000 oak.

- Remove repair sandblast galvanize and replace 12 pair hanging and lodging knees. 40 hours plus $500

- Replace 50% of the hull framing. 700 hours plus $10,000 materials.

- Hatch bases, coamings, footwell. 2 layers plywood, replace king planks and coverboards. 180 hours plus $2,000 materials.

- Glue down 1” pine or fir decking, caulk. 200 hours $4,000 materials

- Install engine beds 20 hours $200 materials.

- Install bulwark stanchions. Plank bulwark, rail cap. 240 hours plus $4,000 materials

- Caulk and pay hull planking 100 hours plus $500.

- The iron floors are good. Wire brush, ospho and paint.

The total now is 1,720 hours which should be multiplied by 1.5 ( some say doubled) you get 2,580 hours. My shop rate in California is currently $60 per hour or $155,000

The materials total $30,000

Work estimate based on 2 skilled experienced shipwrights working together.

At this point you have a sound hull that still needs to be faired and painted. It needs an entire interior including all systems ( engine, electrical, plumbing. It also needs a forward scuttle, skylight, main companionway and cockpit coamings. It needs all spars sails and hardware. I have not estimated any of these as it can be done remotely and is dependant upon owners wishes. A rough estimate would be another $150,000 for all the rest.